Supply management is more than just a buzzword—it’s the backbone of every successful business. From small startups to global corporations, understanding how to optimize supply chains can make or break your operations. Whether you’re a newbie entrepreneur or a seasoned professional, mastering the art of supply is crucial for long-term success. But don’t worry, we’ve got you covered with this ultimate guide packed with actionable insights and real-world examples.

Let’s face it, supply isn’t just about moving goods from point A to point B. It’s about efficiency, cost-saving, and ensuring that your business runs like a well-oiled machine. In today’s competitive market, businesses that neglect their supply chains often find themselves struggling to keep up. So, if you’re ready to level up your game, let’s dive into the nitty-gritty of supply management.

This guide will take you on a journey through the ins and outs of supply chains, from understanding the basics to implementing cutting-edge strategies. We’ll cover everything from inventory management to supplier relationships and beyond. So, grab a coffee, sit back, and let’s get started on mastering the art of supply!

Read also:Antonia Valli The Glamorous Journey Of A Style Icon

Understanding the Basics of Supply

Before we dive deep into the complexities of supply management, let’s break down the basics. What exactly is supply? Simply put, supply refers to the process of sourcing, producing, and delivering goods or services to meet customer demand. It’s the lifeblood of any business, ensuring that products are available when and where they’re needed.

In today’s fast-paced world, businesses face numerous challenges in managing their supply chains. From unpredictable market trends to geopolitical issues, the supply landscape is constantly evolving. That’s why having a solid understanding of supply fundamentals is crucial for navigating these challenges.

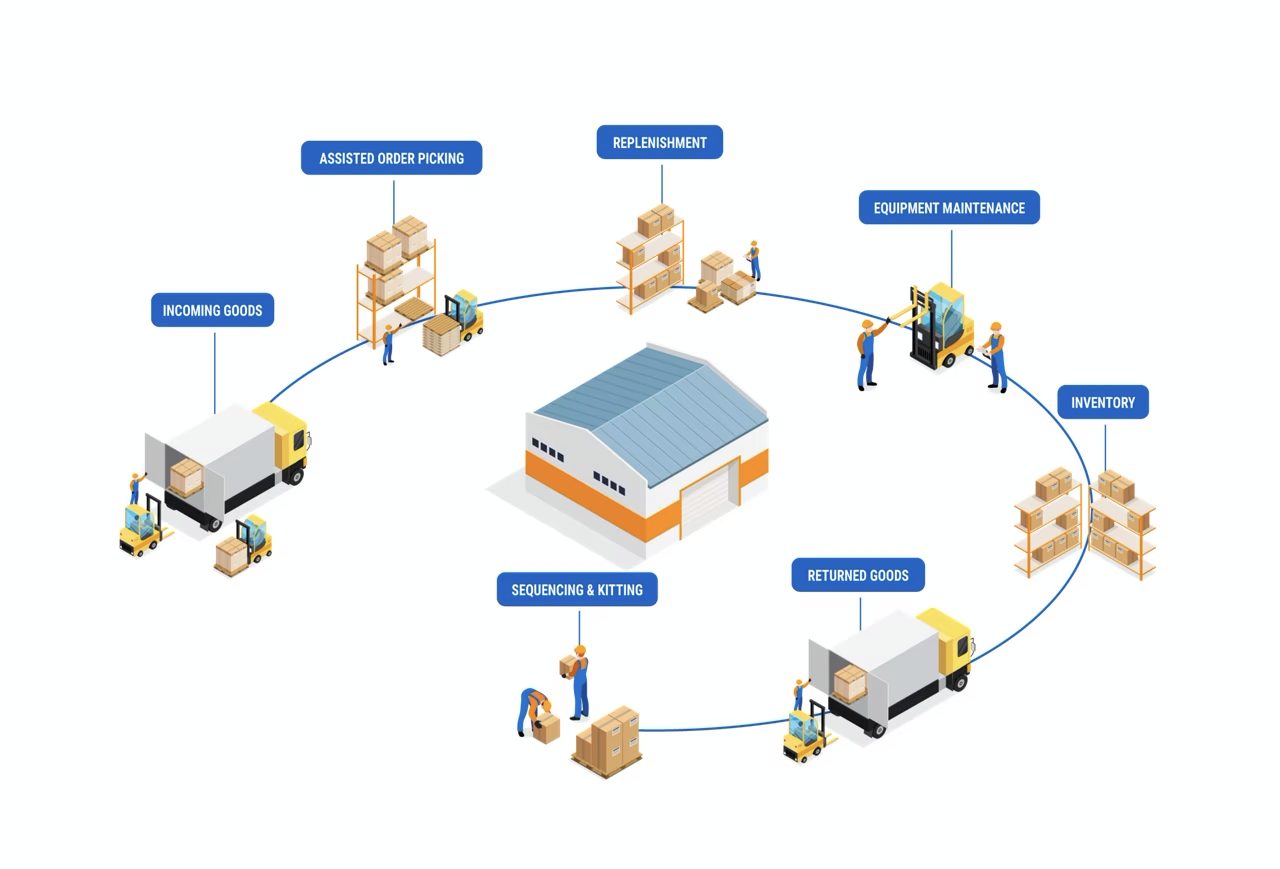

Key Components of Supply Chain Management

To truly master supply, you need to understand its key components. Here’s a quick rundown:

- Procurement: The process of sourcing raw materials and goods from suppliers.

- Inventory Management: Keeping track of stock levels to ensure optimal availability.

- Logistics: The movement and storage of goods from suppliers to customers.

- Distribution: Delivering products to the end consumer in a timely and efficient manner.

Each of these components plays a vital role in the overall supply chain. By optimizing them, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

The Importance of Supply Chain Optimization

Why should you care about supply chain optimization? Well, the answer is simple. A well-optimized supply chain can significantly impact your business’s bottom line. Let’s take a closer look at why this matters:

First and foremost, supply chain optimization leads to cost savings. By streamlining processes and reducing waste, businesses can allocate resources more effectively. This not only boosts profitability but also enhances competitiveness in the market.

Read also:Revolutionize Your Hair Care The Ultimate Guide To Shampoos For Hair Loss

Moreover, an optimized supply chain improves delivery times and enhances customer satisfaction. In today’s instant-gratification world, customers expect fast and reliable delivery. By meeting these expectations, businesses can build trust and loyalty with their customers.

Common Challenges in Supply Chain Management

Of course, managing a supply chain isn’t without its challenges. Here are some of the most common hurdles businesses face:

- Supply Disruptions: Unexpected events like natural disasters or geopolitical tensions can disrupt supply chains.

- Inventory Management: Balancing stock levels to avoid overstocking or understocking can be tricky.

- Technology Integration: Keeping up with the latest technological advancements can be overwhelming.

Despite these challenges, with the right strategies in place, businesses can overcome them and thrive in the long run.

Innovative Strategies for Supply Chain Success

Now that we’ve covered the basics and challenges, let’s talk about some innovative strategies for supply chain success. In today’s digital age, technology plays a pivotal role in transforming supply chains. Here are a few strategies to consider:

First, embrace digital transformation. Tools like AI, blockchain, and IoT are revolutionizing the way businesses manage their supply chains. These technologies offer real-time insights, enhance transparency, and improve decision-making.

Next, focus on building strong supplier relationships. Collaborating with suppliers can lead to mutual benefits, such as improved product quality and reduced costs. It’s all about creating win-win situations for everyone involved.

Tips for Effective Supply Chain Management

Here are some practical tips for effective supply chain management:

- Invest in supply chain analytics to gain valuable insights.

- Implement lean practices to eliminate waste and improve efficiency.

- Stay agile and adaptable to quickly respond to market changes.

By following these tips, businesses can create a robust supply chain that stands the test of time.

The Role of Technology in Supply Chain Management

Technology is transforming the supply chain landscape in unprecedented ways. From automation to data analytics, businesses are leveraging tech solutions to enhance their operations. Let’s explore how technology is reshaping supply chains:

Automation is one of the most significant advancements in supply chain management. By automating repetitive tasks, businesses can reduce human error and increase productivity. This not only saves time but also improves accuracy and reliability.

Additionally, data analytics is playing a crucial role in supply chain optimization. By analyzing vast amounts of data, businesses can identify trends, predict demand, and make informed decisions. This data-driven approach is key to staying ahead in today’s competitive market.

Emerging Technologies in Supply Chain

Here are some emerging technologies that are making waves in the supply chain industry:

- Blockchain: Enhances transparency and traceability in supply chains.

- IoT: Enables real-time monitoring and tracking of goods.

- AI and Machine Learning: Predicts demand and optimizes inventory levels.

These technologies are paving the way for a more connected and efficient supply chain ecosystem.

Sustainable Supply Chain Practices

As businesses become more aware of their environmental impact, sustainable supply chain practices are gaining traction. Consumers are increasingly demanding eco-friendly products, and businesses are responding by adopting greener practices. Here’s how you can make your supply chain more sustainable:

Start by reducing your carbon footprint. Implement energy-efficient processes and use renewable energy sources wherever possible. This not only benefits the environment but also appeals to eco-conscious consumers.

Another approach is to focus on waste reduction. By minimizing waste throughout the supply chain, businesses can conserve resources and reduce costs. It’s a win-win for both the planet and your bottom line.

Benefits of Sustainable Supply Chains

Here are some benefits of adopting sustainable supply chain practices:

- Improved brand reputation and customer loyalty.

- Reduced operational costs and increased efficiency.

- Compliance with environmental regulations and standards.

By prioritizing sustainability, businesses can position themselves as leaders in the industry while contributing to a better future.

Supply Chain Risk Management

Risk management is an essential aspect of supply chain management. With so many variables at play, businesses need to be prepared for the unexpected. Here’s how you can manage risks effectively:

First, conduct a thorough risk assessment. Identify potential risks and develop contingency plans to mitigate them. This proactive approach can save businesses from costly disruptions down the line.

Next, diversify your supplier base. Relying on a single supplier can be risky, especially in uncertain times. By working with multiple suppliers, businesses can ensure a steady flow of goods even if one supplier faces issues.

Best Practices for Supply Chain Risk Management

Here are some best practices for supply chain risk management:

- Regularly review and update risk management strategies.

- Invest in supply chain visibility tools to monitor risks in real-time.

- Build strong relationships with suppliers to enhance collaboration.

By implementing these practices, businesses can safeguard their supply chains against potential risks.

Future Trends in Supply Chain Management

Looking ahead, the supply chain industry is poised for exciting developments. Here are some trends to watch out for:

First, the rise of smart supply chains. With the integration of AI and IoT, supply chains are becoming smarter and more connected. These intelligent systems can predict demand, optimize inventory, and even self-correct when issues arise.

Another trend is the focus on resilience. In the wake of recent global events, businesses are prioritizing resilience in their supply chains. This involves creating flexible systems that can adapt to changing circumstances.

The Future of Supply Chains

As we move forward, the future of supply chains looks promising. Here are some key takeaways:

- Increased adoption of digital technologies to enhance efficiency.

- Growing emphasis on sustainability and ethical practices.

- Greater focus on risk management and resilience.

By embracing these trends, businesses can future-proof their supply chains and thrive in the years to come.

Conclusion: Taking Action on Your Supply Chain

Supply chain management is a critical component of business success. By understanding the basics, addressing challenges, and implementing innovative strategies, businesses can create a robust and efficient supply chain. Remember, the key to success lies in continuous improvement and adaptation.

So, what’s next? We encourage you to take action by reviewing your current supply chain practices and identifying areas for improvement. Share your thoughts in the comments below, and don’t forget to check out our other articles for more valuable insights. Together, let’s master the art of supply and build a better future for your business!

Table of Contents

Understanding the Basics of Supply

The Importance of Supply Chain Optimization

Innovative Strategies for Supply Chain Success

The Role of Technology in Supply Chain Management

Sustainable Supply Chain Practices

Supply Chain Risk Management

Future Trends in Supply Chain Management

![[Infographic] What is supply chain management? Logistics](https://mexicomlogistics.com/wp-content/uploads/2022/09/definition-supply-chain-management-1051x1024.png)